Introduction

In today’s fast-paced industrial landscape, air quality is a growing concern for businesses across Europe. The rise in manufacturing activities, welding processes, and chemical applications has significantly increased the presence of hazardous fumes in workplaces. To address this challenge, mobile fume extraction units have emerged as an essential solution for companies seeking flexibility, efficiency, and compliance with stringent environmental regulations.

This article explores the importance of mobile fume extraction units, their key benefits, industry applications, and factors businesses should consider when investing in these systems.

Understanding Mobile Fume Extraction Units

What Are Mobile Fume Extraction Units?

Mobile fume extraction units are compact, transportable systems designed to capture and filter airborne contaminants directly at the source. Unlike stationary units, these mobile devices provide a high degree of flexibility, making them ideal for dynamic work environments where air purification needs frequently change.

How Do They Work?

Mobile fume extractors utilize powerful suction mechanisms to draw in hazardous fumes and particles generated during industrial processes. The contaminated air passes through multiple filtration stages, often including:

- Pre-filters to capture large particulate matter

- HEPA filters to trap fine airborne particles

- Activated carbon filters to remove harmful gases and odors

Once filtered, clean air is released back into the environment, ensuring safer working conditions for employees.

Key Benefits of Mobile Fume Extraction Units

1. Flexibility and Portability

One of the most significant advantages of mobile fume extraction units is their ability to be moved easily across workspaces. Unlike fixed systems, these units can be deployed where they are needed most, optimizing air filtration in areas prone to high pollutant concentrations.

2. Improved Workplace Safety

Exposure to harmful fumes, such as welding smoke, chemical vapors, and fine dust, can lead to severe health issues, including respiratory diseases and long-term occupational hazards. Mobile fume extraction units help mitigate these risks by capturing contaminants before they reach employees.

3. Compliance with Environmental Regulations

European regulations, including EU OSHA standards and local air quality directives, mandate strict control over workplace emissions. Businesses investing in mobile fume extraction solutions ensure they remain compliant with safety guidelines, avoiding fines and legal complications.

4. Cost-Effective Air Filtration

Compared to large-scale stationary filtration systems, mobile units offer a cost-effective alternative without compromising efficiency. Companies can allocate resources more effectively, deploying extraction units where they are most needed rather than installing permanent ventilation systems throughout the facility.

5. Ease of Maintenance

Mobile fume extractors are designed for user-friendly operation and maintenance. Many models feature easily replaceable filters, intuitive control panels, and durable construction, reducing downtime and maintenance costs.

Industries That Benefit from Mobile Fume Extraction Units

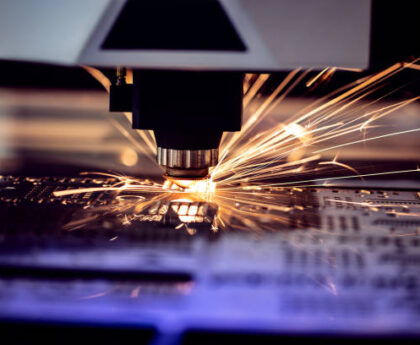

1. Metalworking and Welding

In metal fabrication and welding industries, hazardous fumes containing metal oxides and volatile compounds pose serious health risks. Mobile fume extraction units provide on-the-spot filtration, protecting workers from exposure to toxic welding smoke.

2. Pharmaceutical and Chemical Manufacturing

The production of pharmaceuticals and chemicals involves handling volatile organic compounds (VOCs) and fine powders. Mobile extraction units equipped with activated carbon filters are highly effective in capturing chemical fumes and ensuring compliance with cleanroom standards.

3. Electronics and Semiconductor Manufacturing

Electronics manufacturing often involves soldering and assembly processes that generate fumes containing lead and flux residues. Mobile fume extractors prevent the accumulation of harmful substances, safeguarding both employees and sensitive electronic components.

4. Automotive and Aerospace Industries

Vehicle manufacturing and aircraft maintenance involve painting, sanding, and metal processing activities that release toxic particulates. Mobile fume extraction units are crucial for maintaining clean air quality in production plants and repair facilities.

Key Factors to Consider When Choosing a Mobile Fume Extraction Unit

1. Filtration Efficiency

Businesses should assess the filtration capabilities of different units based on their specific needs. High-efficiency HEPA and activated carbon filters are essential for environments dealing with ultrafine particles and hazardous gases.

2. Airflow Capacity

The airflow rate of an extraction unit determines its effectiveness in capturing contaminants. Companies must select models with adequate CFM (cubic feet per minute) ratings to match the size and intensity of their industrial processes.

3. Mobility and Design

An ideal mobile fume extraction unit should be lightweight, compact, and equipped with durable wheels for easy maneuverability. Ergonomic handles and flexible extraction arms further enhance usability in dynamic workspaces.

4. Noise Levels

Since industrial environments already produce significant noise pollution, selecting low-noise fume extractors ensures a more comfortable and productive work setting.

5. Energy Efficiency

Energy-efficient models reduce power consumption while maintaining high-performance air filtration. Opting for units with eco-friendly motor designs can significantly lower operational costs.

The Future of Mobile Fume Extraction Technologies

Advancements in air purification technology continue to shape the future of mobile fume extraction. Here are some of the latest trends:

- IoT-Enabled Monitoring: Smart sensors allow real-time tracking of air quality and system performance, enabling predictive maintenance.

- Self-Cleaning Filters: New-generation extractors feature automatic filter-cleaning mechanisms, reducing maintenance downtime.

- Compact, High-Power Designs: Improvements in motor efficiency and filter technology are making mobile units more powerful while remaining compact and lightweight.

- Sustainable Materials: Manufacturers are exploring recyclable and biodegradable filter materials to enhance environmental sustainability.

Conclusion

Mobile fume extraction units represent a crucial investment for European businesses striving to maintain workplace safety, regulatory compliance, and operational efficiency. With their portability, high filtration efficiency, and cost-effectiveness, these systems provide a practical solution for industries dealing with hazardous airborne contaminants.

As companies continue to prioritize air quality and worker safety, integrating advanced mobile fume extraction technologies will be key to achieving sustainable, health-conscious industrial operations. Whether in welding workshops, pharmaceutical labs, or automotive plants, adopting these innovative air filtration systems ensures a cleaner, safer future for industries across Europe.